Visit Cascade TEK at Space Tech Expo USA 2019

Cascade TEK is exhibiting at this year's Space Tech Expo USA. Space Tech Expo USA unites thousands of industry leaders, decision makers, engineers, specifiers and buyers with the manufacturers and supply chain for civil, military and commercial space to network, discover the latest innovations, and grow their businesses. The Space Tech Conference runs alongside the expo and welcomes space and defense executives and technical leaders to hear industry heavyweights share their technical expertise, real-world case studies, and insights on industry trends. Monday May 20, 2019 - 5:00pm-9:00pm Exhibition Preview (exhibitors and invited guests) Tuesday...

Cascade TEK SpaceCom 2018

SpaceCom 2018 is the only civilian conference and exposition where NASA, aerospace, and industry come together to connect. It’s where professionals from the aerospace and commercial sectors convene for two days to gain insights during forward-looking conference sessions, see firsthand, cutting-edge technology in an interactive exhibit hall and participate in NASA presentations and an Entrepreneur Summit that promises to transform markets. Visit us at Booth 339 November 26-28th!...

Space Sim Conference

Cascade TEK is attending the 30th Space Simulation Conference. Space Sim is a major international forum in space hardware environmental testing for research and development and qualification. It provides a unique opportunity for engineers and scientists from industry, government, and academia to present and exchange information and ideas on simulating the space environment to develop and test space mission hardware. Visit us at Booth #16 November 5 - 8, 2018!...

We’re at CAMX 2018!

[gallery ids="12938"] Our booth at CAMX 2018 is all set up. Come by and see us October 16-18th at Booth #E85!...

Visit Cascade TEK at CAMX 2018

Cascade TEK will be exhibiting at CAMX! Regardless of the application — transportation, aerospace, marine, wind energy, software, construction and infrastructure, medical, academics, sports and leisure — CAMX is the must-attend event for products, solutions, networking, and advanced industry thinking. Come by and see us October 16-18th at Booth #E85!...

Announcing Cascade TEK’s New TFO Forced Air Lab Ovens!

Cascade TEK ovens are ideal for critical scientific research, analytical, and laboratory use. The TFO model ovens are also suitable for use on the production floor and beyond. Typical applications include aging, curing, drying, baking, pre-heating, conditioning and life cycle testing. TFO ovens are available in 110-120v, 50/60Hz or 220-240V, 50/60Hz configurations and achieve temperatures up to 306° with fast ramp-up and recovery time. Features for the Cascade TEK Forced Air Ovens: All new design, updated control panel, upgraded mechanisms Available in three cabinet sizes: 1.4 cu.ft., 3 cu.ft, 4.9 cu.ft. ...

Cascade TEK Ovens Acquired by Sheldon Manufacturing Inc.

Cascade TEK ovens division is now a proud member of the Sheldon Manufacturing family of brands. Cascade TEK was founded with a primary product focus on vacuum and forced air ovens. These products serve the industrial, aerospace, medical device, electronics an semiconductor markets along with many others. Cascade TEK ovens are designed and manufactured in accordance with ISO 9001:2015 to better comply with the robust compliance needs of these industrial customers. “Our aim is to increase our market share with Cascade TEK’s turnkey, automated drying systems and hi-vacuum expertise for aerospace markets...

Vacuum Pumps – What The Gunk?

Cascade TEK makes sure we pair the right vacuum pump to our vacuum ovens. We ask a lot of questions to make sure our vacuum ovens are built to execute your process. This picture is an example of what a vacuum pump can going through. Let us help you get the proper vacuum pump for your application! Ask for Jeremy!...

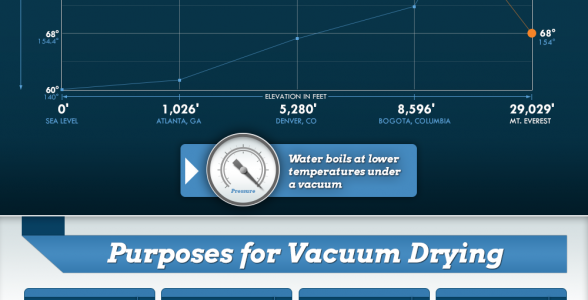

The Science of Vacuum Oven Drying [Infographic]

how exactly does vacuum drying work? What is the process behind vacuum drying? This infographic explains how a change in pressure (pull a vacuum) can successfully dry products at low temperatures. ...

- 1

- 2