Product Description

Cascade TEK’s SVO-10-VC is built to execute your exact drying process. Vacuum drying is the most efficient method to remove moisture – especially from temperature sensitive products.

SVO-10-VC Oven with Vacuum Control

This feature allows the operator to manually operate the vacuum system, or use profiles in the Watlow controller to operate the vacuum system in the oven. The vacuum system includes an electro-pneumatic isolation valve installed between the oven and vacuum pump. This valve is controlled by an event output in the Watlow controller. The operator can turn this event on by pressing a button on the controller. The valve will open and the vacuum pump will evacuate the oven down to the ultimate pressure rating of the vacuum pump. When the process is complete, the operator turns off the vacuum event and the oven will automatically backfill to 600 Torr. This backfill limit is controlled by a set point in the digital vacuum gauge controller and can be adjusted by the operator if a different level is desired. It can also be set to not auto backfill if desired. The SVO-10-VC can also be programmed to perform this function in a recipe in conjunction with heating allowing multiple pump purge & heating cycles to help remove moisture from the product without the need for the operator to control the oven.

Includes upgraded Inficon (1000 Torr to 0.1 mTorr) Pirani Full Range Digital Vacuum Gauge to allow for reading the full ultimate vacuum of the process/pump. Includes upgraded Inficon (1000 to 1.0 Torr) Capacitance Manometer Vacuum Gauge to allow for vacuum control via the setpoint of the process/pump.

Standard Features

Glass Viewing Window

Inert gas backfill Connection

Stainless Steel Interior

Aluminum Shelves

Powder Coated Steel Exterior

Spare KF-25 Access Port

Watlow F4T Touchscreen Temperature Controller –

• Includes 2 USB hosts, USB configuration port, standard bus, Ethernet Modbus® TCP

• Recipe based PID Temperature Control. 40 Ramp and Soak recipes with up to 50 total steps per recipe.

• Digital Integrated Over Temperature Limit

• Analog Outputs

• NEW email/text notifications

UL 61010-1, EN 61010-1, CSA 61010-1, CE, SAFETY CERTIFICATIONS

Optional Features

Vacuum Setpoint Control

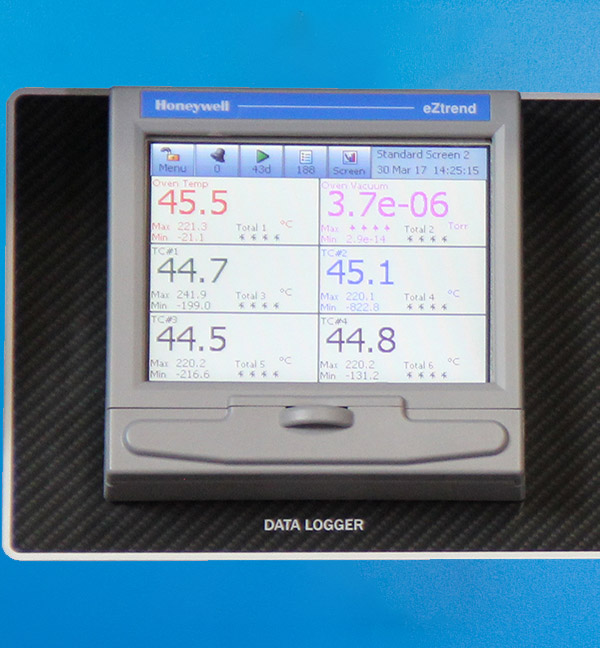

Digital Datalogger

Feedthrough’s

Heated/Cooled Platen (-100C to +220C)

Calibration

Factory Acceptance Testing

Vacuum Theory Training

Customized to Meet Your Specific Application

Cascade TEK understands that every requirement is unique. We do not pair a generic vacuum pump with each oven. We help determine the correct pump to meet your exact requirements. Let us help you choose the correct vacuum pump and connection kit:

• See our favorite vacuum pumps

• See our list of connection kits and other vacuum accessories